Start from: The Easilys menu.

- Navigate to Supplier Orders > Order Preparation.

- By default, the calculations on the Order Preparation screen are based on menus and forecasted headcounts (possibly supplemented by guest orders). This is the typical calculation mode used in institutional catering or any organisation using menus. For this mode, the top toggle must be set to “From menus.”

- If you are a production lab type of structure with child sites placing product orders through the supplier orders screen, and you use the Site Supply screen (in Shipping), set the top toggle on the screen to “From site orders.”

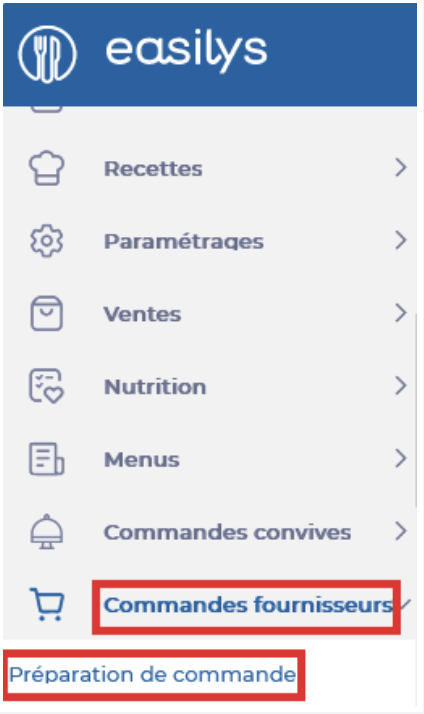

- If you use the Sales Forecast screen (in the Sales menu), keep the top toggle set to “From menus” and check “Include sales forecasts” in the Menu template filter.

Once you have selected the correct mode for your use case, continue as described below.

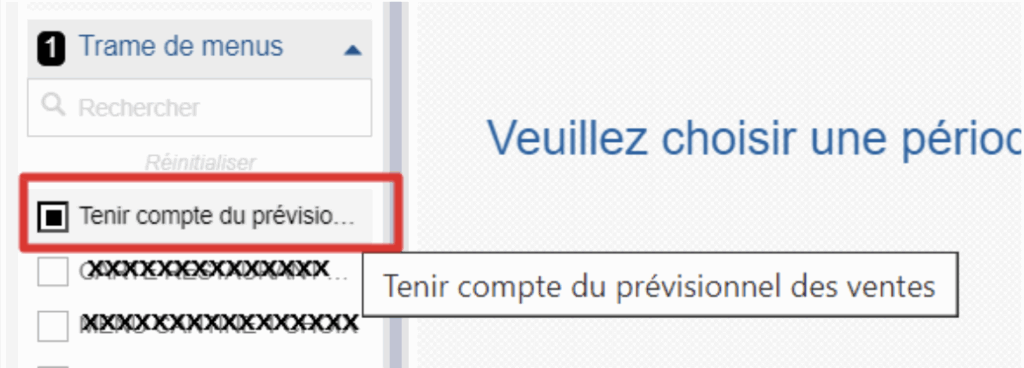

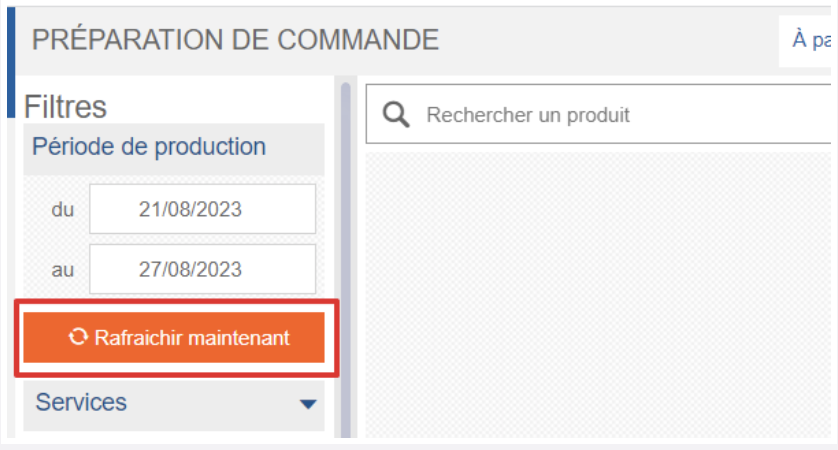

- Indicate for which period you want the application to calculate the needs by using the "Production period" filter.

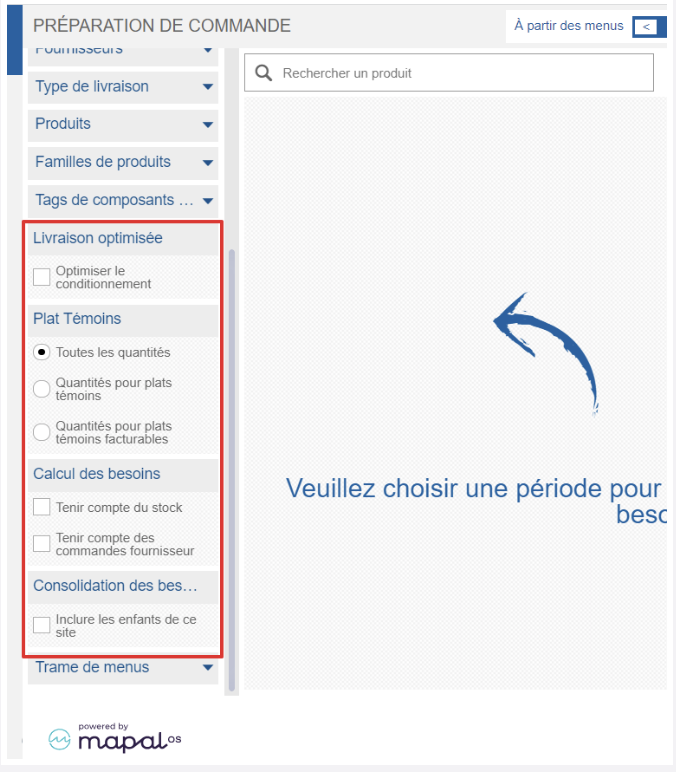

- You can tick the "Optimise packaging" box. This allows you to manage needs according to the packaging modes configured in Production.

- You can tick the "Include child sites" box if needed. This allows you to obtain the needs for all sites.

Note: This option is not available if the calculation mode (top toggle) is set to From site orders.

- You can tick the "Include stock" box so that Easilys takes into account the quantities already in stock.

- You can tick the "Include supplier orders" box so that Easilys takes into account both the needs and the orders in "In progress", "Pending", and "Sent" status.

Note: To use the options "Include stock" and "Include supplier orders", you must generate the needs from today’s date, otherwise the calculation will be incorrect.

- Select Refresh now in the "Production period" filter to launch the calculation of needs, which will then be displayed on the screen.

If there are no headcounts on the recipes in your menus (or, depending on the selected calculation mode, no orders from your child sites or no sales forecast), the application considers the need to be 0, and no items are proposed in the list of products to order.

Check the list of needs, adjust if needed

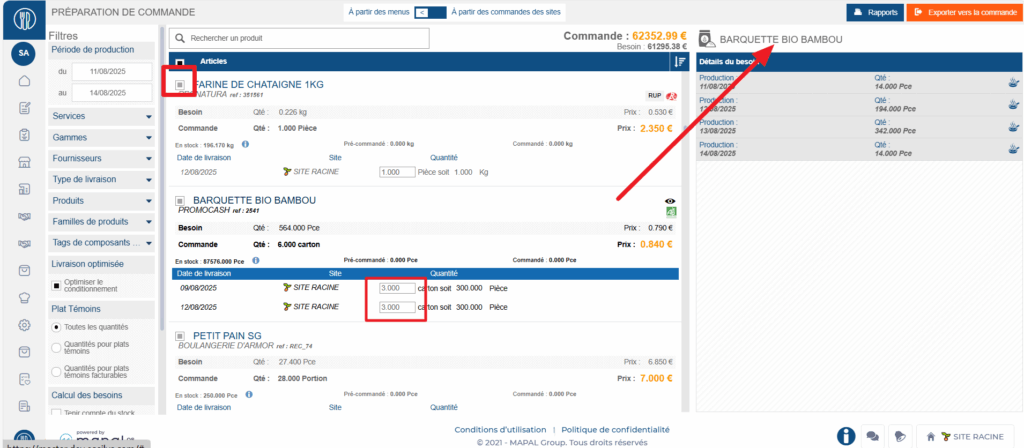

- You can search for a product in the list using the filters or the search bar.

- Select a product to see the details of the need.

- You can modify the quantities if needed.

- You can uncheck the box to include the product so that this need is not taken into account when generating the order baskets from this list.

The colour of the product name provides information:

- The product name is in GREY

These are generic ingredients and not products. They appear this way because no supplier product is linked to them. You must manually link them. - The product name is in RED

Red indicates that the selected supplier products do not fully meet the existing Smart Selection criteria. They are still orderable. - The product name is in BLUE

Blue indicates that the selected supplier products meet the existing Smart Selection criteria. If no Smart Selection rule is in place, supplier products still appear in BLUE.

Note: If the message "No compatible delivery date found" is displayed, it means that the order lead time entered on the supplier file does not allow the product to be ordered in time for the need.

Generate order baskets from this needs list

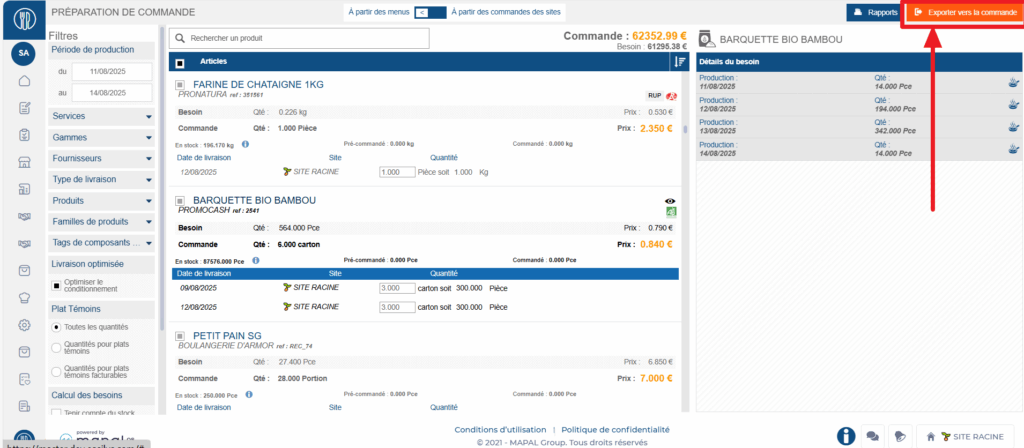

- Select Export to Order.

The application creates the order baskets in the SUPPLIER ORDERS screen where you can send them.